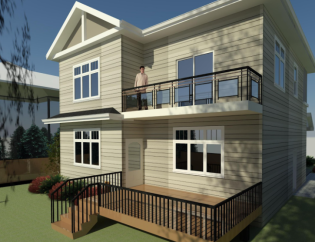

A safe railing is not just about how it looks. It is about how it is built. Even the highest-quality railing materials can fall short if the posts are not spaced properly or securely anchored. At MR Engineering, we recently assessed a deck railing system for a homeowner who wanted to make a few changes. They planned to adjust the spacing between posts and replace the original blocking. On paper, it sounded simple. But in reality, these changes could have a big impact on the railing’s strength, safety, and compliance with building codes.

Taking a Closer Look at the Existing Setup

The original railing had square posts spaced eight feet apart. Each post sat on a 3-ply 2"× 8" solid blocking assembly under the deck. While it worked, this design can make it harder to meet safety load requirements, especially when the distance between posts is on the larger side. Longer spans mean more stress on each connection, and without reinforcement, that can lead to wobbles, sagging, or worse.

In our review, we found that swapping the 3-ply blocking for a single-ply member could be safe, but only if the post spacing was reduced to five feet. This would give the railing the extra strength it needed to handle the required loads. We also recommended installing eight structural screws, with four in each direction, to lock everything in place and keep the railing steady.

What the Building Codes Say

Building codes, like the International Residential Code (IRC), set clear rules for railings. They need to handle a concentrated load of 200 pounds anywhere along the top rail, a uniform load of 50 pounds per linear foot, and an infill load of 50 pounds per square foot. Once post spacing stretches beyond six feet, it is harder to meet these standards without specialized materials or reinforcements.

For some railing styles, such as cable railings, the maximum spacing is even shorter, often four to five feet, to control deflection and meet the “4-inch sphere” safety rule. At eight feet, very few systems could pass these tests without extra support.

Our Recommendations for a Stronger Railing

For this project, our focus was on making the railing safer, sturdier, and more durable. Reducing the post spacing to five feet was the first step. Using through-bolts or high-strength structural screws made sure each post was firmly anchored to the rim joist. Adding solid blocking or steel connectors to the rim reduced the chance of posts twisting or shifting over time.

With these upgrades, the modified railing would not just pass code. It would feel solid and reliable every time someone leaned on it.

Why Getting a Structural Assessment Matters

A railing might look fine, but without a proper assessment, you cannot be sure it is safe. Our job is to check the current setup, understand how any changes will affect it, and make sure it meets the right standards. We look at how much weight it can take, how it is connected, and what condition the materials are in. Then we give clear, practical recommendations that keep people safe and avoid future headaches.

By making these checks early, homeowners and contractors can save time, money, and stress. Whether you are building from scratch, upgrading a deck, or making changes to your railing, MR Engineering can help you be confident that it is safe, compliant, and built to last.

Key Takeaways

- Strong, well-spaced posts are the backbone of a safe railing.

- Small changes to spacing or connections can have a big impact on safety.

- A structural assessment from MR Engineering gives you peace of mind before you build.